Top Applications of CI and DI Casting Products in Industrial and Municipal Sectors

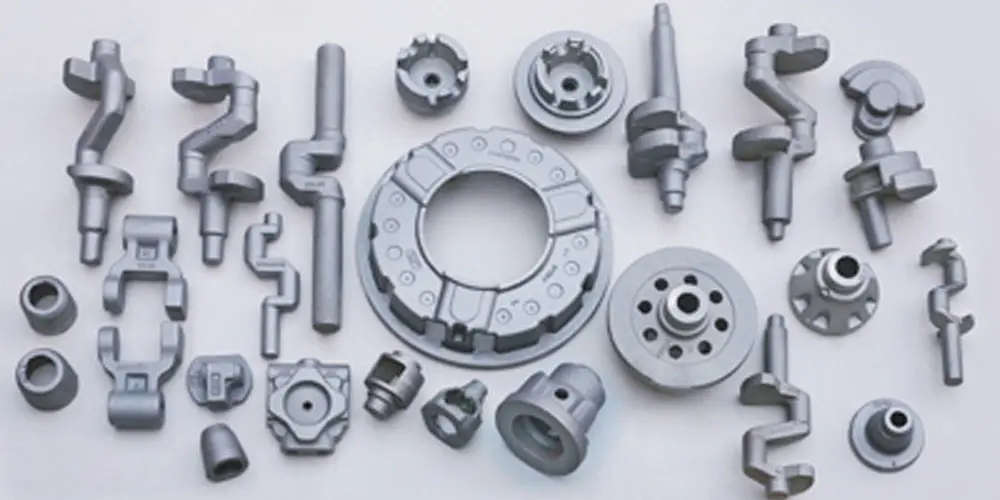

Cast Iron (CI) and Ductile Iron (DI) castings have been an integral part of industrial and municipal infrastructure for decades. These materials are known for their strength, durability, and cost-effectiveness, making them ideal for various applications. Both CI and DI castings are widely used across multiple industries due to their superior mechanical properties, which allow them to withstand heavy loads and harsh environments. In this article, we will explore some of the top applications of CI and DI casting products in industrial and municipal sectors.

1. Valves and Pipe Fittings

CI and DI castings are commonly used in the manufacturing of valves and pipe fittings for industrial and municipal applications. These products are essential for controlling and regulating the flow of fluids in pipelines. DI castings, in particular, are favored for their enhanced strength and resistance to impact, making them suitable for high-pressure and high-stress environments. These castings are used in water supply systems, sewage systems, oil and gas pipelines, and chemical plants, ensuring reliable and efficient operation.

2. Water and Sewerage Infrastructure

One of the most common applications of DI and CI castings is in municipal water and sewerage systems. DI pipes, fittings, and manhole covers are used extensively in drinking water supply systems, stormwater drains, and wastewater treatment plants. These products are designed to handle the pressure and environmental stress typical in such applications. The corrosion-resistant properties of DI and CI castings ensure long-lasting performance even in challenging underground environments.

3. Automotive Components

In the automotive industry, both CI and DI castings are used to manufacture a variety of components, including engine blocks, brake components, and suspension parts. DI castings are particularly favored for their excellent tensile strength and ductility, making them ideal for parts that require both strength and flexibility. Cast iron components provide the necessary durability to withstand the demanding conditions of modern vehicles.

4. Industrial Machinery

CI and DI castings play a crucial role in the manufacturing of industrial machinery. Components such as housings, bases, and frames are often made from CI or DI due to their ability to withstand heavy loads and vibrations. These castings ensure the stability and longevity of industrial equipment used in manufacturing, mining, and construction.

5. Heavy Equipment

DI and CI castings are essential in the production of parts for heavy machinery and construction equipment. These castings are used to produce components like gearboxes, shafts, and structural frames, which require both strength and durability. The robustness of DI and CI castings allows them to handle the intense wear and tear typical in construction and mining equipment.

6. Manhole Covers and Grates

In municipal infrastructure, CI and DI castings are often used to create manhole covers and grates. These products need to be durable enough to withstand constant vehicular traffic and harsh weather conditions. DI castings, with their high tensile strength, are ideal for these applications, ensuring they maintain their structural integrity under heavy loads.

7. Fire Hydrants

Fire hydrants, critical for firefighting operations, are often made from CI or DI castings. These products need to be able to endure high pressures and outdoor elements, including exposure to water and extreme temperatures. DI casting's corrosion resistance and strength make it the preferred material for manufacturing long-lasting, reliable fire hydrants.

8. Agricultural Machinery

In agriculture, CI and DI castings are used to manufacture components for machinery such as plows, harrows, and tillers. These castings provide the necessary toughness to handle the rough terrain and heavy-duty tasks associated with agricultural work. The longevity and wear resistance of CI and DI castings ensure that agricultural machinery remains in working condition for extended periods, reducing maintenance costs.

9. Street Furniture

In urban areas, CI and DI castings are commonly used in the production of street furniture, including park benches, bollards, and lamp posts. These products are designed to be both functional and aesthetically pleasing. The durability of CI and DI ensures that these fixtures can withstand exposure to weather elements, heavy use, and potential vandalism, providing long-lasting infrastructure for public spaces.

10. Structural Supports

CI and DI castings are frequently used in the construction industry for structural supports, columns, and beams. Their high compressive strength makes them ideal for supporting heavy loads in bridges, buildings, and other infrastructure projects. These castings contribute to the stability and safety of structures, ensuring they can withstand environmental pressures and human activity.

Conclusion

CI and DI castings play a vital role in various sectors, from municipal water systems to industrial machinery and automotive components. Their strength, durability, and versatility make them the material of choice for numerous applications across different industries. With their excellent performance in demanding environments, CI and DI castings continue to be indispensable in creating reliable, long-lasting infrastructure and machinery. Whether used in valves, fire hydrants, heavy equipment, or street furniture, these products are essential for the functioning and growth of both industrial and municipal sectors.